Understanding Spark Plug Torque: Why It Matters

Spark plugs are crucial for your car’s engine performance. They ignite the air-fuel mixture, initiating the combustion process. Proper spark plug installation is paramount. This includes achieving the correct torque. Too little torque can lead to leaks and poor combustion. Too much torque can damage the spark plug or the cylinder head. Getting it right ensures optimal engine efficiency and longevity.

The Right Torque: A Vehicle-Specific Value

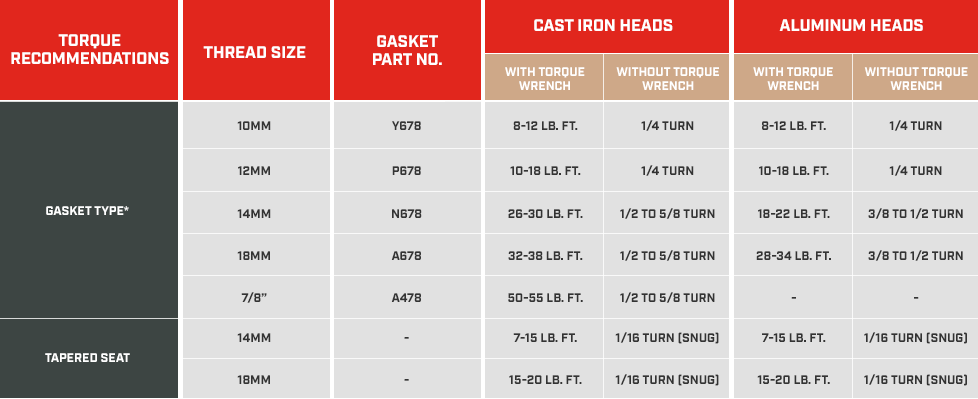

There’s no one-size-fits-all answer to the question of how much torque for a car spark plug. The correct torque specification varies depending on several factors. These include:

- Spark Plug Type: Different spark plugs (e.g., copper, iridium, platinum) have different torque requirements.

- Thread Size: Spark plugs come in various thread sizes (e.g., 14mm, 18mm).

- Cylinder Head Material: Aluminum cylinder heads are more susceptible to damage than cast iron ones.

- Whether or not you are using anti-seize compound.

Always consult your vehicle’s repair manual or the spark plug manufacturer’s specifications for the precise torque value. Ignoring these specifications can lead to serious engine damage;

Tools of the Trade: What You’ll Need

Before you begin, gather the necessary tools:

- Torque Wrench: Essential for accurate torque application.

- Spark Plug Socket: A specialized socket with a rubber insert to protect the spark plug.

- Socket Wrench: To attach to the spark plug socket.

- Extension: May be needed to reach recessed spark plugs.

- Gap Tool: To ensure the spark plug gap is correct.

- Anti-Seize Compound (Optional): Use sparingly, and only if recommended by the spark plug manufacturer.

Having the right tools makes the job easier and safer.

Step-by-Step Installation: Achieving the Correct Torque

Follow these steps for proper spark plug installation:

- Remove the Old Spark Plug: Carefully disconnect the spark plug wire or coil pack and remove the old spark plug.

- Inspect the New Spark Plug: Check the spark plug for any damage and ensure the gap is correct. Adjust the gap if necessary using a gap tool.

- Apply Anti-Seize (If Recommended): Apply a very small amount of anti-seize compound to the spark plug threads, if recommended by the manufacturer.

- Hand-Tighten the Spark Plug: Carefully thread the spark plug into the cylinder head by hand until it is snug.

- Torque to Specification: Using a torque wrench, tighten the spark plug to the specified torque value.

- Reconnect the Wire or Coil Pack: Reconnect the spark plug wire or coil pack.

Important Note: Over-torquing is a common mistake. It can strip the threads in the cylinder head, requiring costly repairs. Always double-check the torque specification and use a calibrated torque wrench.

FAQ: Frequently Asked Questions

What happens if I overtighten a spark plug?

Overtightening can damage the spark plug, strip the threads in the cylinder head, and potentially crack the insulator. This can lead to engine misfires and costly repairs.

Can I use anti-seize compound on spark plugs?

Some manufacturers recommend using anti-seize compound, while others advise against it. Consult the spark plug manufacturer’s instructions. If using anti-seize, apply it sparingly.

How often should I replace my spark plugs?

The replacement interval varies depending on the type of spark plug and your vehicle’s manufacturer recommendations. Consult your owner’s manual for the recommended interval. Typically, spark plugs should be replaced every 30,000 to 100,000 miles.

What if I don’t have a torque wrench?

While it’s possible to install spark plugs without a torque wrench, it’s highly discouraged. A torque wrench ensures accurate torque application, preventing damage to the spark plugs and cylinder head. Consider borrowing or purchasing a torque wrench for this task.

Spark plugs are crucial for your car’s engine performance. They ignite the air-fuel mixture, initiating the combustion process. Proper spark plug installation is paramount. This includes achieving the correct torque. Too little torque can lead to leaks and poor combustion. Too much torque can damage the spark plug or the cylinder head. Getting it right ensures optimal engine efficiency and longevity.

There’s no one-size-fits-all answer to the question of how much torque for a car spark plug. The correct torque specification varies depending on several factors. These include:

- Spark Plug Type: Different spark plugs (e.g;, copper, iridium, platinum) have different torque requirements.

- Thread Size: Spark plugs come in various thread sizes (e.g., 14mm, 18mm).

- Cylinder Head Material: Aluminum cylinder heads are more susceptible to damage than cast iron ones.

- Whether or not you are using anti-seize compound.

Always consult your vehicle’s repair manual or the spark plug manufacturer’s specifications for the precise torque value. Ignoring these specifications can lead to serious engine damage.

Before you begin, gather the necessary tools:

- Torque Wrench: Essential for accurate torque application.

- Spark Plug Socket: A specialized socket with a rubber insert to protect the spark plug.

- Socket Wrench: To attach to the spark plug socket.

- Extension: May be needed to reach recessed spark plugs.

- Gap Tool: To ensure the spark plug gap is correct.

- Anti-Seize Compound (Optional): Use sparingly, and only if recommended by the spark plug manufacturer.

Having the right tools makes the job easier and safer.

Follow these steps for proper spark plug installation:

- Remove the Old Spark Plug: Carefully disconnect the spark plug wire or coil pack and remove the old spark plug.

- Inspect the New Spark Plug: Check the spark plug for any damage and ensure the gap is correct. Adjust the gap if necessary using a gap tool.

- Apply Anti-Seize (If Recommended): Apply a very small amount of anti-seize compound to the spark plug threads, if recommended by the manufacturer.

- Hand-Tighten the Spark Plug: Carefully thread the spark plug into the cylinder head by hand until it is snug.

- Torque to Specification: Using a torque wrench, tighten the spark plug to the specified torque value.

- Reconnect the Wire or Coil Pack: Reconnect the spark plug wire or coil pack.

Important Note: Over-torquing is a common mistake. It can strip the threads in the cylinder head, requiring costly repairs. Always double-check the torque specification and use a calibrated torque wrench.

Overtightening can damage the spark plug, strip the threads in the cylinder head, and potentially crack the insulator. This can lead to engine misfires and costly repairs.

Some manufacturers recommend using anti-seize compound, while others advise against it. Consult the spark plug manufacturer’s instructions. If using anti-seize, apply it sparingly.

The replacement interval varies depending on the type of spark plug and your vehicle’s manufacturer recommendations. Consult your owner’s manual for the recommended interval. Typically, spark plugs should be replaced every 30,000 to 100,000 miles.

While it’s possible to install spark plugs without a torque wrench, it’s highly discouraged. A torque wrench ensures accurate torque application, preventing damage to the spark plugs and cylinder head. Consider borrowing or purchasing a torque wrench for this task.

Advanced Considerations: Torque Angle and Thread Condition

Beyond the basic torque specification, certain advanced considerations can further refine the installation process and ensure optimal performance. These include torque angle tightening and meticulous inspection of thread condition.

Torque Angle Tightening

Some manufacturers specify a torque angle tightening procedure, particularly for newer engine designs. This involves tightening the spark plug to a preliminary torque value, followed by an additional rotation measured in degrees (e.g., 90 degrees, 180 degrees). This method provides a more precise clamping force and compensates for variations in thread friction. Always adhere strictly to the manufacturer’s specified torque angle if indicated.

Thread Condition Assessment

Prior to installing a new spark plug, thoroughly inspect the threads in the cylinder head. Damaged or corroded threads can significantly affect the accuracy of the torque reading and compromise the seal. If thread damage is evident, consider using a thread chaser or tap to restore the threads to their original condition. In severe cases, professional thread repair may be necessary to prevent future issues.

Troubleshooting Common Issues: Misfires and Torque-Related Problems

Even with meticulous installation, issues can sometimes arise. Recognizing and addressing torque-related problems promptly is crucial for maintaining engine health.

- Misfires: A common symptom of improperly torqued spark plugs is engine misfires. This can manifest as rough idling, reduced power, and poor fuel economy. Check the spark plug torque and condition if misfires occur shortly after spark plug replacement.

- Spark Plug Loosening: Insufficient torque can cause spark plugs to loosen over time, leading to compression leaks and engine damage. Regularly inspect spark plugs for tightness, especially in high-performance applications.

- Damaged Threads: Overtightening can strip the threads in the cylinder head, requiring costly repairs. If you suspect thread damage, consult a qualified mechanic for assessment and repair options.

The Importance of Regular Maintenance: Ensuring Long-Term Performance

Spark plug maintenance extends beyond initial installation. Regular inspection and replacement are essential for maintaining optimal engine performance and preventing costly repairs.

Adhering to the manufacturer’s recommended replacement interval is crucial. As spark plugs age, their electrodes erode, leading to reduced spark intensity and decreased combustion efficiency. This can result in reduced power, increased fuel consumption, and higher emissions. Regularly inspect spark plugs for signs of wear, such as electrode erosion, carbon fouling, or cracked insulators. Replace spark plugs as needed to maintain peak engine performance.

Best Practice: Keep a detailed maintenance log of all spark plug replacements, including the date, mileage, and spark plug type used. This will help you track your maintenance schedule and ensure timely replacements.