Decoding the Combustion Chamber: How Does a Modern Car Engine Work?

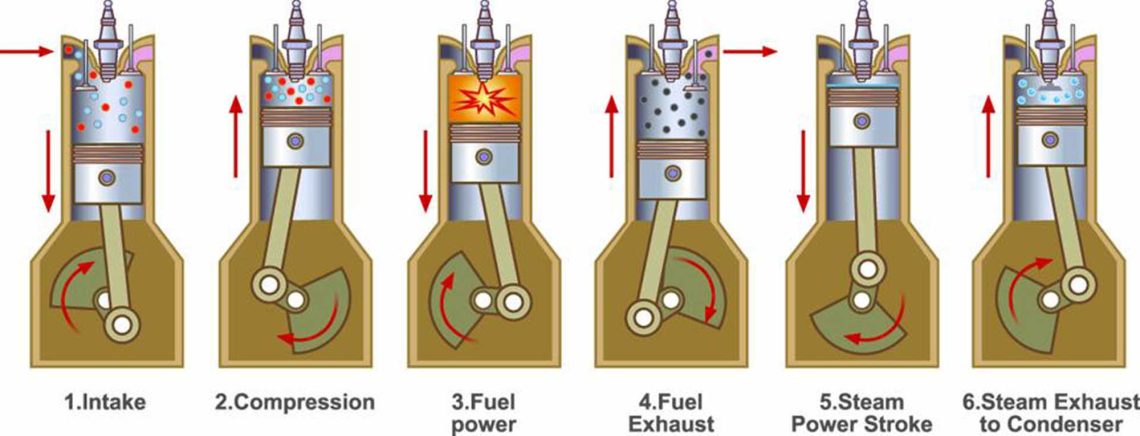

The Four-Stroke Cycle: The Heartbeat of Your Car

At the core of most modern car engines lies the four-stroke combustion cycle, also known as the Otto cycle. This cycle, repeated continuously, converts the chemical energy of fuel into mechanical energy that ultimately powers your wheels. It’s a marvel of engineering, and understanding it provides a fundamental grasp of how your car moves.

The four strokes are:

- Intake: The piston moves down, drawing a mixture of air and fuel into the cylinder.

- Compression: The piston moves up, compressing the air-fuel mixture. This increases its temperature and prepares it for ignition.

- Combustion (Power): The spark plug ignites the compressed mixture, causing a rapid expansion of gases that forces the piston down. This is where the power is generated.

- Exhaust: The piston moves up again, pushing the burnt gases out of the cylinder through the exhaust valve.

Each stroke is crucial, and their precise timing is managed by the engine’s control systems.

Tip: Regular oil changes are vital for maintaining the smooth operation of the four-stroke cycle. Clean oil lubricates the moving parts, reducing friction and wear.

Fuel Injection: Precision Delivery

Modern car engines almost universally use fuel injection systems. These systems precisely meter and spray fuel into the intake manifold or directly into the cylinder. This contrasts with older carburetor systems, which were less efficient and less precise.

Fuel injectors are controlled by the engine control unit (ECU), which uses sensors to monitor various engine parameters, such as:

- Engine speed (RPM)

- Throttle position

- Airflow

- Coolant temperature

Based on this data, the ECU calculates the optimal amount of fuel to inject for efficient combustion and performance.

Ignition System: Sparking the Power

The ignition system is responsible for creating the spark that ignites the air-fuel mixture. Modern engines use electronic ignition systems, which are more reliable and efficient than older mechanical systems. These systems typically consist of:

- Ignition coil: Generates a high-voltage electrical pulse.

- Spark plugs: Located in each cylinder, they provide the spark that ignites the air-fuel mixture.

- Distributor (or coil-on-plug system): Distributes the high-voltage pulse to the correct spark plug at the correct time. Many modern cars use coil-on-plug systems, where each spark plug has its own dedicated coil, eliminating the need for a distributor.

The timing of the spark is crucial for optimal engine performance and fuel efficiency. The ECU controls the ignition timing based on engine speed, load, and other factors.

Interesting Fact: The timing of the spark can be advanced or retarded to optimize performance and fuel economy under different driving conditions.

Engine Control Unit (ECU): The Brain of the Operation

The ECU, also known as the engine control module (ECM), is the central computer that manages all aspects of the engine’s operation. It receives data from various sensors, processes that data, and controls the fuel injection, ignition, and other systems to optimize performance, fuel efficiency, and emissions.

The ECU also performs diagnostic functions, monitoring the engine for problems and storing diagnostic trouble codes (DTCs) if any issues are detected. These DTCs can be read by a mechanic using a diagnostic scan tool.

Key Functions of the ECU:

- Fuel injection control

- Ignition timing control

- Idle speed control

- Emissions control

- Diagnostic monitoring

FAQ: Understanding Your Engine

Q: What is the difference between a gasoline and a diesel engine?

A: Gasoline engines use spark plugs to ignite the air-fuel mixture, while diesel engines rely on compression to heat the air to a temperature high enough to ignite the fuel. Diesel engines are generally more fuel-efficient but produce more particulate emissions.

Q: What is turbocharging?

A: Turbocharging is a method of forcing more air into the engine cylinders, which allows for more fuel to be burned and thus increases power output. A turbocharger uses exhaust gases to spin a turbine, which in turn compresses the intake air.

Q: How often should I change my engine oil?

A: The recommended oil change interval varies depending on the vehicle and the type of oil used. Consult your owner’s manual for specific recommendations. Generally, changing your oil every 5,000 to 7,500 miles is a good practice.

Variable Valve Timing (VVT): Optimizing Airflow

Variable Valve Timing (VVT) is a sophisticated technology employed in modern engines to enhance performance, fuel economy, and reduce emissions. Traditional engines have fixed valve timing, meaning the intake and exhaust valves open and close at predetermined points in the engine cycle. VVT systems, however, allow the engine control unit (ECU) to dynamically adjust the valve timing based on engine speed, load, and other operating conditions.

This adjustment is typically achieved through the use of hydraulically or electrically actuated mechanisms that alter the relationship between the camshaft and the crankshaft. By optimizing valve timing, VVT can improve:

- Low-end torque: By opening the intake valves earlier at low engine speeds, VVT can increase cylinder filling and improve torque output.

- High-end power: By opening the intake valves later at high engine speeds, VVT can reduce pumping losses and improve power output.

- Fuel efficiency: By optimizing valve timing for different operating conditions, VVT can reduce fuel consumption.

- Emissions: By improving combustion efficiency, VVT can reduce harmful emissions.

Several variations of VVT exist, including variable valve lift (VVL), which allows for adjustment of the valve lift in addition to timing.

Cooling System: Maintaining Optimal Temperature

The engine cooling system is critical for preventing overheating and ensuring optimal engine performance. Combustion generates significant heat, and without an effective cooling system, the engine components could be damaged or even destroyed. The cooling system typically consists of:

- Radiator: Dissipates heat from the coolant to the atmosphere.

- Water pump: Circulates coolant throughout the engine and radiator.

- Thermostat: Regulates the flow of coolant to maintain a consistent engine temperature.

- Coolant: A mixture of water and antifreeze that absorbs heat from the engine and transfers it to the radiator.

- Cooling fan: Assists in dissipating heat from the radiator, especially at low speeds.

Modern cooling systems often incorporate electronic controls to optimize cooling performance and prevent overheating under extreme conditions. Regular maintenance of the cooling system, including coolant flushes and inspections of hoses and belts, is essential for preventing costly repairs.

Important Note: Never remove the radiator cap when the engine is hot. The cooling system is pressurized, and removing the cap can result in scalding hot coolant spraying out.

Lubrication System: Reducing Friction and Wear

The lubrication system is responsible for delivering oil to all moving parts of the engine, reducing friction and wear. Without adequate lubrication, engine components would quickly overheat and fail. The lubrication system typically consists of:

- Oil pump: Circulates oil throughout the engine.

- Oil filter: Removes contaminants from the oil.

- Oil pan: Stores the oil.

- Oil galleries: Passages that deliver oil to the various engine components.

The oil not only lubricates but also helps to cool the engine by carrying away heat. Regular oil changes are crucial for maintaining the cleanliness and effectiveness of the oil. The type of oil used is also important and should be selected based on the manufacturer’s recommendations.

Exhaust System: Managing Combustion Byproducts

The exhaust system is responsible for safely and efficiently removing the byproducts of combustion from the engine. It also plays a role in reducing noise and emissions. The exhaust system typically consists of:

- Exhaust manifold: Collects exhaust gases from the cylinders.

- Catalytic converter: Reduces harmful emissions by converting pollutants into less harmful substances.

- Muffler: Reduces noise from the exhaust gases;

- Tailpipe: Discharges the exhaust gases into the atmosphere.

Modern exhaust systems often incorporate oxygen sensors that provide feedback to the ECU, allowing it to optimize fuel injection and ignition timing for reduced emissions. The catalytic converter is a critical component for meeting emissions standards and requires periodic inspection to ensure proper function.