Sludge Slayer: Mastering Car Engine Sludge Removal for Peak Performance Understanding Engine Sludge: The Silent Killer

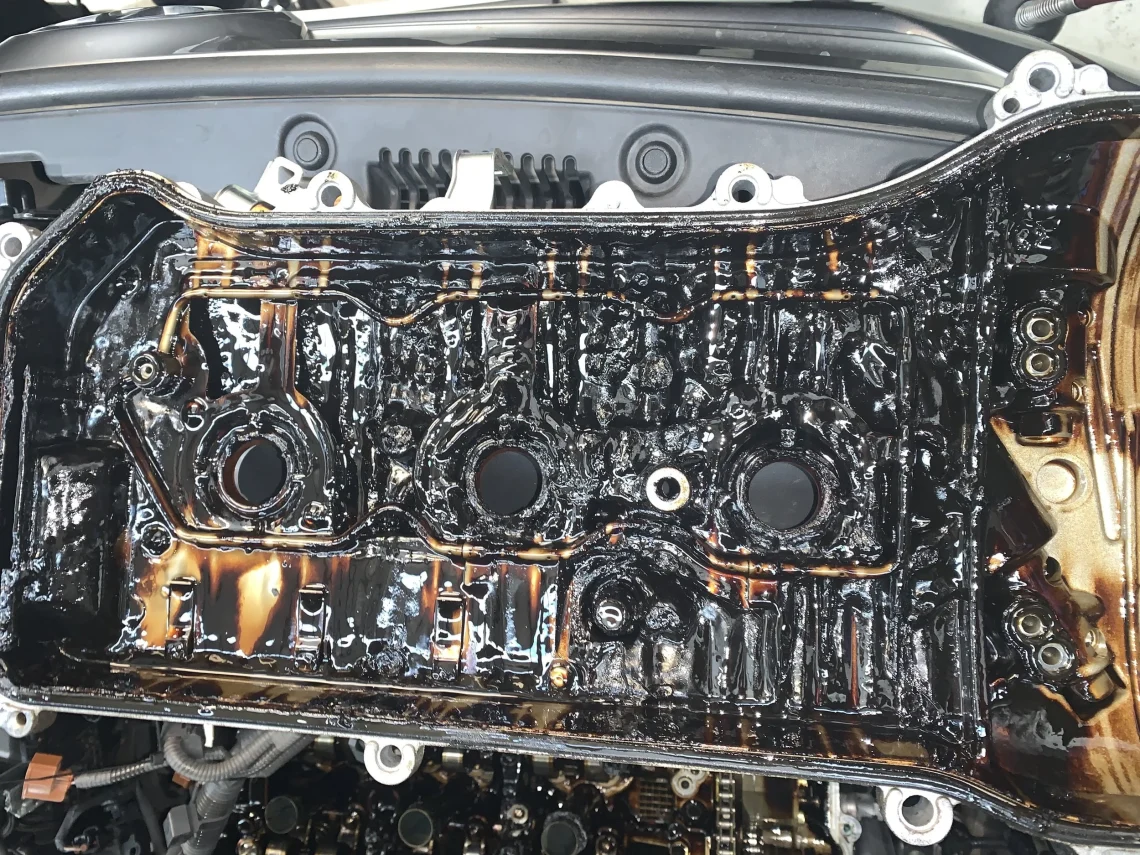

Engine sludge is a thick, dark deposit that forms inside your engine․ It’s a nasty combination of oxidized oil, combustion byproducts, and contaminants․ Left unchecked, it can severely impact your engine’s performance and lifespan․ We’re talking reduced fuel efficiency, increased wear and tear, and even catastrophic engine failure․ It’s crucial to understand what causes it and how to prevent it․

Several factors contribute to sludge buildup:

- Infrequent oil changes

- Low-quality oil

- Short trips (engine doesn’t reach operating temperature)

- Overheating

- Contamination from coolant leaks

Regular car engine sludge removal is paramount for maintaining optimal engine health․ Think of it as a vital part of your car’s preventative maintenance․ By removing sludge, you’re essentially giving your engine a fresh start, allowing it to operate more efficiently and reliably․ This translates to better fuel economy, reduced emissions, and a longer engine lifespan․ Don’t underestimate the power of a clean engine!

Pro Tip: Consider using a high-quality synthetic oil․ Synthetic oils are more resistant to breakdown and oxidation, which helps to minimize sludge formation․

Ignoring sludge buildup can lead to:

- Reduced oil flow

- Increased friction and wear

- Overheating

- Decreased engine power

- Potential engine failure

Methods for Car Engine Sludge Removal

There are several methods for tackling engine sludge, ranging from simple oil changes to more aggressive chemical treatments․ The best approach depends on the severity of the sludge buildup․

1․ Regular Oil Changes

This is the most basic and essential step․ Adhering to your vehicle manufacturer’s recommended oil change intervals is crucial․ Use a high-quality oil and filter․

2․ Engine Flush

Engine flushes involve adding a chemical cleaner to your engine oil and running the engine for a short period before draining the oil․ This helps to loosen and dissolve sludge deposits․ However, use caution, as some flushes can be harsh on older engines․ Always follow the manufacturer’s instructions carefully․

3․ Professional Cleaning

For severe sludge buildup, consider taking your vehicle to a professional mechanic․ They have specialized equipment and expertise to thoroughly clean your engine without causing damage․ This might involve disassembling parts of the engine for manual cleaning․

Important Note: If your engine has a history of severe sludge buildup, consult with a qualified mechanic before attempting any aggressive cleaning methods․ You don’t want to dislodge large chunks of sludge that could clog oil passages․

Preventing Future Sludge Buildup

Prevention is always better than cure․ Here are some tips to keep your engine sludge-free:

- Use high-quality oil: Synthetic oils offer superior protection against sludge formation․

- Change your oil regularly: Follow your vehicle manufacturer’s recommended oil change intervals․

- Avoid short trips: Allow your engine to reach its operating temperature to burn off moisture and contaminants․

- Address leaks promptly: Coolant leaks can contaminate your oil and contribute to sludge buildup․

- Consider an oil analysis: Regular oil analysis can help you monitor the condition of your oil and detect early signs of sludge formation․

FAQ: Car Engine Sludge Removal Q: How often should I change my oil?

A: Refer to your vehicle manufacturer’s recommendations․ Generally, it’s every 3,000-5,000 miles for conventional oil and 7,500-10,000 miles for synthetic oil․

Q: Can I use an engine flush on an older engine?

A: Use caution․ Engine flushes can be harsh on older engines․ Consult with a mechanic before using one․

Q: What are the signs of engine sludge?

A: Common signs include reduced fuel economy, decreased engine power, and a knocking or ticking noise from the engine․

Q: Is it safe to drive with engine sludge?

A: It’s not recommended․ Engine sludge can cause serious damage to your engine․ Address the issue as soon as possible․

Sludge Slayer: Mastering Car Engine Sludge Removal for Peak Performance Engine sludge is a thick, dark deposit that forms inside your engine․ It’s a nasty combination of oxidized oil, combustion byproducts, and contaminants․ Left unchecked, it can severely impact your engine’s performance and lifespan․ We’re talking reduced fuel efficiency, increased wear and tear, and even catastrophic engine failure․ It’s crucial to understand what causes it and how to prevent it․

Several factors contribute to sludge buildup:

- Infrequent oil changes

- Low-quality oil

- Short trips (engine doesn’t reach operating temperature)

- Overheating

- Contamination from coolant leaks

Regular car engine sludge removal is paramount for maintaining optimal engine health․ Think of it as a vital part of your car’s preventative maintenance․ By removing sludge, you’re essentially giving your engine a fresh start, allowing it to operate more efficiently and reliably․ This translates to better fuel economy, reduced emissions, and a longer engine lifespan․ Don’t underestimate the power of a clean engine!

Pro Tip: Consider using a high-quality synthetic oil․ Synthetic oils are more resistant to breakdown and oxidation, which helps to minimize sludge formation․

Ignoring sludge buildup can lead to:

- Reduced oil flow

- Increased friction and wear

- Overheating

- Decreased engine power

- Potential engine failure

There are several methods for tackling engine sludge, ranging from simple oil changes to more aggressive chemical treatments․ The best approach depends on the severity of the sludge buildup․

This is the most basic and essential step․ Adhering to your vehicle manufacturer’s recommended oil change intervals is crucial․ Use a high-quality oil and filter․

Engine flushes involve adding a chemical cleaner to your engine oil and running the engine for a short period before draining the oil․ This helps to loosen and dissolve sludge deposits; However, use caution, as some flushes can be harsh on older engines․ Always follow the manufacturer’s instructions carefully․

For severe sludge buildup, consider taking your vehicle to a professional mechanic․ They have specialized equipment and expertise to thoroughly clean your engine without causing damage․ This might involve disassembling parts of the engine for manual cleaning․

Important Note: If your engine has a history of severe sludge buildup, consult with a qualified mechanic before attempting any aggressive cleaning methods․ You don’t want to dislodge large chunks of sludge that could clog oil passages․

Prevention is always better than cure․ Here are some tips to keep your engine sludge-free:

- Use high-quality oil: Synthetic oils offer superior protection against sludge formation․

- Change your oil regularly: Follow your vehicle manufacturer’s recommended oil change intervals․

- Avoid short trips: Allow your engine to reach its operating temperature to burn off moisture and contaminants․

- Address leaks promptly: Coolant leaks can contaminate your oil and contribute to sludge buildup․

- Consider an oil analysis: Regular oil analysis can help you monitor the condition of your oil and detect early signs of sludge formation․

A: Refer to your vehicle manufacturer’s recommendations․ Generally, it’s every 3,000-5,000 miles for conventional oil and 7,500-10,000 miles for synthetic oil․

A: Use caution․ Engine flushes can be harsh on older engines․ Consult with a mechanic before using one․

A: Common signs include reduced fuel economy, decreased engine power, and a knocking or ticking noise from the engine․

A: It’s not recommended․ Engine sludge can cause serious damage to your engine․ Address the issue as soon as possible․

Advanced Diagnostic Techniques for Sludge Detection

Beyond the aforementioned symptomatic indicators, several advanced diagnostic techniques can be employed to ascertain the presence and severity of engine sludge․ These methods provide a more definitive assessment, enabling informed decisions regarding remediation strategies․

1․ Oil Pressure Analysis

A significant drop in oil pressure, particularly at idle, can be indicative of restricted oil flow due to sludge accumulation within the oil pump or oil galleries․ A pressure gauge should be utilized to monitor oil pressure under various operating conditions․ Deviations from the manufacturer’s specified pressure range warrant further investigation․

2․ Visual Inspection via Oil Fill Cap

A preliminary visual inspection can be conducted by removing the oil fill cap and examining the underside of the cap and the visible engine components․ The presence of thick, dark, tar-like deposits is a strong indicator of sludge․ However, this method provides only a limited view and may not reveal the full extent of the problem․

3․ Borescope Inspection

A borescope, or inspection camera, can be inserted through the oil fill port or other access points to visually inspect internal engine components, such as the valve train and cylinder head․ This allows for a more comprehensive assessment of sludge buildup in areas that are not readily accessible․

4․ Oil Filter Examination

Carefully dissecting a used oil filter can reveal the presence of sludge and other contaminants․ The filter media should be examined for excessive debris and discoloration․ A heavily contaminated filter is a clear indication of internal engine issues․

Considerations for Chemical Engine Flush Procedures

While chemical engine flushes can be effective in dissolving and removing sludge, it is imperative to exercise caution and adhere to best practices to minimize the risk of adverse effects․ The following considerations are crucial:

- Compatibility: Ensure that the chosen engine flush is compatible with your vehicle’s engine type and the type of oil being used․ Consult the product manufacturer’s specifications and your vehicle’s owner’s manual․

- Dosage: Strictly adhere to the recommended dosage instructions provided by the engine flush manufacturer․ Overdosing can lead to excessive cleaning and potential damage to seals and gaskets․

- Duration: Do not exceed the recommended engine running time specified by the manufacturer․ Prolonged exposure to the chemical cleaner can compromise the integrity of engine components․

- Post-Flush Oil Change: Immediately after completing the engine flush procedure, drain the old oil and replace it with fresh, high-quality oil and a new oil filter․ This is essential to remove any residual cleaner and dissolved sludge․

- Pre-Existing Conditions: Exercise extreme caution when using engine flushes on engines with a history of high mileage or known pre-existing conditions, such as leaks or worn seals․ The cleaning action of the flush may exacerbate these issues․

Expert Insight: Prior to performing an engine flush, consider performing a compression test to assess the overall health of the engine․ A low compression reading may indicate underlying issues that could be aggravated by the cleaning process․

The Role of Oil Analysis in Sludge Management

Regular oil analysis is a proactive approach to monitoring engine health and detecting early signs of sludge formation․ By analyzing a sample of used engine oil, valuable information can be obtained regarding the oil’s condition, the presence of contaminants, and the wear patterns within the engine․

Key Parameters Analyzed in Oil Analysis: - Viscosity: Measures the oil’s resistance to flow, indicating its ability to lubricate engine components effectively․

- Total Base Number (TBN): Indicates the oil’s ability to neutralize acids formed during combustion․ A declining TBN suggests that the oil is becoming depleted and less effective at protecting against corrosion;

- Acid Number (AN): Measures the acidity of the oil, indicating the presence of oxidation products and other contaminants․

- Wear Metals: Detects the presence of metals such as iron, copper, aluminum, and lead, which are indicative of wear within the engine․

- Contaminants: Identifies the presence of contaminants such as coolant, fuel, and dirt, which can contribute to sludge formation and engine damage․

By tracking these parameters over time, trends can be identified that may indicate the onset of sludge formation or other engine problems․ This allows for timely intervention and preventative maintenance, potentially avoiding costly repairs․

Understanding Engine Sludge: The Silent Killer

Engine sludge is a thick, dark deposit that forms inside your engine․ It’s a nasty combination of oxidized oil, combustion byproducts, and contaminants․ Left unchecked, it can severely impact your engine’s performance and lifespan․ We’re talking reduced fuel efficiency, increased wear and tear, and even catastrophic engine failure․ It’s crucial to understand what causes it and how to prevent it․

Several factors contribute to sludge buildup:

- Infrequent oil changes

- Low-quality oil

- Short trips (engine doesn’t reach operating temperature)

- Overheating

- Contamination from coolant leaks

Regular car engine sludge removal is paramount for maintaining optimal engine health․ Think of it as a vital part of your car’s preventative maintenance․ By removing sludge, you’re essentially giving your engine a fresh start, allowing it to operate more efficiently and reliably․ This translates to better fuel economy, reduced emissions, and a longer engine lifespan․ Don’t underestimate the power of a clean engine!

Pro Tip: Consider using a high-quality synthetic oil․ Synthetic oils are more resistant to breakdown and oxidation, which helps to minimize sludge formation․

Ignoring sludge buildup can lead to:

- Reduced oil flow

- Increased friction and wear

- Overheating

- Decreased engine power

- Potential engine failure

Methods for Car Engine Sludge Removal

There are several methods for tackling engine sludge, ranging from simple oil changes to more aggressive chemical treatments․ The best approach depends on the severity of the sludge buildup․

1․ Regular Oil Changes

This is the most basic and essential step․ Adhering to your vehicle manufacturer’s recommended oil change intervals is crucial․ Use a high-quality oil and filter․

2․ Engine Flush

Engine flushes involve adding a chemical cleaner to your engine oil and running the engine for a short period before draining the oil․ This helps to loosen and dissolve sludge deposits․ However, use caution, as some flushes can be harsh on older engines․ Always follow the manufacturer’s instructions carefully․

3․ Professional Cleaning

For severe sludge buildup, consider taking your vehicle to a professional mechanic․ They have specialized equipment and expertise to thoroughly clean your engine without causing damage․ This might involve disassembling parts of the engine for manual cleaning․

Important Note: If your engine has a history of severe sludge buildup, consult with a qualified mechanic before attempting any aggressive cleaning methods․ You don’t want to dislodge large chunks of sludge that could clog oil passages․

Preventing Future Sludge Buildup

Prevention is always better than cure․ Here are some tips to keep your engine sludge-free:

- Use high-quality oil: Synthetic oils offer superior protection against sludge formation․

- Change your oil regularly: Follow your vehicle manufacturer’s recommended oil change intervals․

- Avoid short trips: Allow your engine to reach its operating temperature to burn off moisture and contaminants․

- Address leaks promptly: Coolant leaks can contaminate your oil and contribute to sludge buildup․

- Consider an oil analysis: Regular oil analysis can help you monitor the condition of your oil and detect early signs of sludge formation․

FAQ: Car Engine Sludge Removal Q: How often should I change my oil?

A: Refer to your vehicle manufacturer’s recommendations․ Generally, it’s every 3,000-5,000 miles for conventional oil and 7,500-10,000 miles for synthetic oil․

Q: Can I use an engine flush on an older engine?

A: Use caution․ Engine flushes can be harsh on older engines․ Consult with a mechanic before using one․

Q: What are the signs of engine sludge?

A: Common signs include reduced fuel economy, decreased engine power, and a knocking or ticking noise from the engine․

Q: Is it safe to drive with engine sludge?

A: It’s not recommended․ Engine sludge can cause serious damage to your engine․ Address the issue as soon as possible․

Engine sludge is a thick, dark deposit that forms inside your engine․ It’s a nasty combination of oxidized oil, combustion byproducts, and contaminants․ Left unchecked, it can severely impact your engine’s performance and lifespan․ We’re talking reduced fuel efficiency, increased wear and tear, and even catastrophic engine failure․ It’s crucial to understand what causes it and how to prevent it․

Several factors contribute to sludge buildup:

- Infrequent oil changes

- Low-quality oil

- Short trips (engine doesn’t reach operating temperature)

- Overheating

- Contamination from coolant leaks

Regular car engine sludge removal is paramount for maintaining optimal engine health․ Think of it as a vital part of your car’s preventative maintenance․ By removing sludge, you’re essentially giving your engine a fresh start, allowing it to operate more efficiently and reliably․ This translates to better fuel economy, reduced emissions, and a longer engine lifespan․ Don’t underestimate the power of a clean engine!

Pro Tip: Consider using a high-quality synthetic oil․ Synthetic oils are more resistant to breakdown and oxidation, which helps to minimize sludge formation․

Ignoring sludge buildup can lead to:

- Reduced oil flow

- Increased friction and wear

- Overheating

- Decreased engine power

- Potential engine failure

There are several methods for tackling engine sludge, ranging from simple oil changes to more aggressive chemical treatments․ The best approach depends on the severity of the sludge buildup․

This is the most basic and essential step․ Adhering to your vehicle manufacturer’s recommended oil change intervals is crucial․ Use a high-quality oil and filter․

Engine flushes involve adding a chemical cleaner to your engine oil and running the engine for a short period before draining the oil․ This helps to loosen and dissolve sludge deposits; However, use caution, as some flushes can be harsh on older engines․ Always follow the manufacturer’s instructions carefully․

For severe sludge buildup, consider taking your vehicle to a professional mechanic․ They have specialized equipment and expertise to thoroughly clean your engine without causing damage․ This might involve disassembling parts of the engine for manual cleaning․

Important Note: If your engine has a history of severe sludge buildup, consult with a qualified mechanic before attempting any aggressive cleaning methods․ You don’t want to dislodge large chunks of sludge that could clog oil passages․

Prevention is always better than cure․ Here are some tips to keep your engine sludge-free:

- Use high-quality oil: Synthetic oils offer superior protection against sludge formation․

- Change your oil regularly: Follow your vehicle manufacturer’s recommended oil change intervals․

- Avoid short trips: Allow your engine to reach its operating temperature to burn off moisture and contaminants․

- Address leaks promptly: Coolant leaks can contaminate your oil and contribute to sludge buildup․

- Consider an oil analysis: Regular oil analysis can help you monitor the condition of your oil and detect early signs of sludge formation․

A: Refer to your vehicle manufacturer’s recommendations․ Generally, it’s every 3,000-5,000 miles for conventional oil and 7,500-10,000 miles for synthetic oil․

A: Use caution․ Engine flushes can be harsh on older engines․ Consult with a mechanic before using one․

A: Common signs include reduced fuel economy, decreased engine power, and a knocking or ticking noise from the engine․

A: It’s not recommended․ Engine sludge can cause serious damage to your engine․ Address the issue as soon as possible․

Advanced Diagnostic Techniques for Sludge Detection

Beyond the aforementioned symptomatic indicators, several advanced diagnostic techniques can be employed to ascertain the presence and severity of engine sludge․ These methods provide a more definitive assessment, enabling informed decisions regarding remediation strategies․

1․ Oil Pressure Analysis

A significant drop in oil pressure, particularly at idle, can be indicative of restricted oil flow due to sludge accumulation within the oil pump or oil galleries․ A pressure gauge should be utilized to monitor oil pressure under various operating conditions․ Deviations from the manufacturer’s specified pressure range warrant further investigation․

2․ Visual Inspection via Oil Fill Cap

A preliminary visual inspection can be conducted by removing the oil fill cap and examining the underside of the cap and the visible engine components․ The presence of thick, dark, tar-like deposits is a strong indicator of sludge․ However, this method provides only a limited view and may not reveal the full extent of the problem․

3․ Borescope Inspection

A borescope, or inspection camera, can be inserted through the oil fill port or other access points to visually inspect internal engine components, such as the valve train and cylinder head․ This allows for a more comprehensive assessment of sludge buildup in areas that are not readily accessible․

4․ Oil Filter Examination

Carefully dissecting a used oil filter can reveal the presence of sludge and other contaminants․ The filter media should be examined for excessive debris and discoloration․ A heavily contaminated filter is a clear indication of internal engine issues․

Considerations for Chemical Engine Flush Procedures

While chemical engine flushes can be effective in dissolving and removing sludge, it is imperative to exercise caution and adhere to best practices to minimize the risk of adverse effects․ The following considerations are crucial:

- Compatibility: Ensure that the chosen engine flush is compatible with your vehicle’s engine type and the type of oil being used․ Consult the product manufacturer’s specifications and your vehicle’s owner’s manual․

- Dosage: Strictly adhere to the recommended dosage instructions provided by the engine flush manufacturer․ Overdosing can lead to excessive cleaning and potential damage to seals and gaskets․

- Duration: Do not exceed the recommended engine running time specified by the manufacturer․ Prolonged exposure to the chemical cleaner can compromise the integrity of engine components․

- Post-Flush Oil Change: Immediately after completing the engine flush procedure, drain the old oil and replace it with fresh, high-quality oil and a new oil filter․ This is essential to remove any residual cleaner and dissolved sludge․

- Pre-Existing Conditions: Exercise extreme caution when using engine flushes on engines with a history of high mileage or known pre-existing conditions, such as leaks or worn seals․ The cleaning action of the flush may exacerbate these issues․

Expert Insight: Prior to performing an engine flush, consider performing a compression test to assess the overall health of the engine․ A low compression reading may indicate underlying issues that could be aggravated by the cleaning process․

The Role of Oil Analysis in Sludge Management

Regular oil analysis is a proactive approach to monitoring engine health and detecting early signs of sludge formation․ By analyzing a sample of used engine oil, valuable information can be obtained regarding the oil’s condition, the presence of contaminants, and the wear patterns within the engine․

Key Parameters Analyzed in Oil Analysis: - Viscosity: Measures the oil’s resistance to flow, indicating its ability to lubricate engine components effectively․

- Total Base Number (TBN): Indicates the oil’s ability to neutralize acids formed during combustion․ A declining TBN suggests that the oil is becoming depleted and less effective at protecting against corrosion;

- Acid Number (AN): Measures the acidity of the oil, indicating the presence of oxidation products and other contaminants․

- Wear Metals: Detects the presence of metals such as iron, copper, aluminum, and lead, which are indicative of wear within the engine․

- Contaminants: Identifies the presence of contaminants such as coolant, fuel, and dirt, which can contribute to sludge formation and engine damage․

By tracking these parameters over time, trends can be identified that may indicate the onset of sludge formation or other engine problems․ This allows for timely intervention and preventative maintenance, potentially avoiding costly repairs․